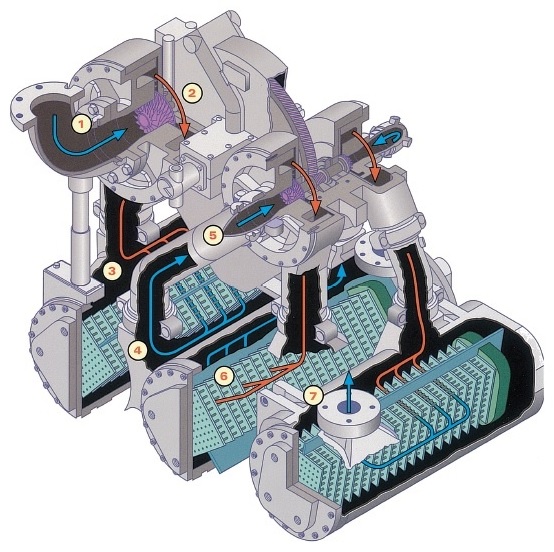

氣體經由進氣控制閥進入壓縮機的第一段葉輪。

Air flows in from the inlet valve, then goes to the first stage impeller.

氣體通過第一段葉輪旋轉帶動後,流速快速提高,藉由進入徑向的擴壓盤,速度能轉換成壓力能,經渦殼導流進入第一段中間冷卻器。

After being compressed, the air flows to the first stage intercooler.

壓縮後的高溫氣體進入第一段中間冷卻器,經其冷卻水管束及散熱鰭片進行熱交換後,氣體被冷卻。

水走管內的直通管設計,更便於冷卻器的清潔及維護,可維持冷卻器的最佳換熱效果。

When the high temperature compressed air flows through the first stage intercooler, the air’s temperature will be cooldown.

冷卻後的氣體以較低的流速離開第一段中間冷卻器管束,進入塗有防鏽塗層的中冷室,經過90度的轉和向上型空氣流道轉向設計,將冷凝水進一步從氣體中分離出來 (因此無需再增設高維修率的除霧墊 demister-pad)。冷凝水將通過位於中間冷卻器底部的洩水閥排放到機組外面。

The cooled gas leaves the first intercooler tube bundle at a lower flow rate and enters the intercooling chamber coated with a rust-proof coating. After 90 degrees of rotation and upward air flow path design, the condensate is further removed from the gas (Therefore, there is no need to add a high maintenance rate demister pad). Condensate is discharge to the outside of the unit through a drain valve located at the bottom of the intercooler.

氣體離開第一段中間冷卻器,進入第二段進氣管道。然後在第二段葉輪、擴壓盤和渦殼中進行再次壓縮過程。

The gas enters the second stage impeller for the second time compressor.

壓縮後高溫氣體從渦殼排出進入第二段中間冷卻器,然後在第二段中間冷卻器中重複冷卻過程。冷卻後的氣體從第二段中間冷卻器離開,進入進氣管道,經由第三段葉輪、擴壓盤和渦殼進行第三次壓縮。

The compressed high temperature gas is discharge from the volute into the second stage intercooler, and then the cooling process is repeated in the second stage intercooler. The cooled gas leaves the second stage intercooler, enters the inlet tube, and undergoes a third compression by the third stage impeller, diffuser and volute.

經過第三次壓縮的高溫高壓氣體將經由後部冷卻器進行最終的冷卻,冷卻後的高壓低溫壓縮氣體將離開離心機而進入系統管路。

After the third compression, the high temperature pressure gas will go through the rear cooler for the final cooling. The cooled high pressure and low temperature compressed air will leave the centrifuge and enter the system pipe.

二、產品及控制簡介 Introduction to Products and Controls